WHEN QUALITY, PERFORMANCE AND RELIABILITY ARE WHAT YOU NEED

THEN LOOK NO FURTHER THAN CAMCO LUBRICANTS. DELIVERING THE BEST REFRIGERATION OILS FOR OVER 30 YEARS.

CAMCO Ammonia Refrigeration Oils

Here are the most popular CAMCO series for ammonia refrigeration systems:

This series features premier fluids for today’s ammonia service, with outstanding stability, no sludge-forming tendencies, and superior stamina (outlasting mineral oils 4-8 times).

This is a synthetic hydrocarbon-based fluid that is designed for the new, extremely low temperature ammonia applications (less than -45°C/-49°F). It has pour points as low as -51°C/-59.8°F.

This product was designed for use in Cornell ammonia refrigeration pumps.

A 100% Synthetic Hydrocarbon based lubricant including specially designed additives for ammonia compressors or harsh environments with a patented Seal Conditioner to: protect against corrosion, oxidation, and thermal breakdown; improve coalescing; and prevent foaming. Used for applications where the lubricant is subjected to certain harsh chemical environments.

CAMCO® SAB-68 is truly a wax-free 100% Synthetic Hydrocarbon fluid containing Polyalphaolefin and Alkylated Benzene based lubricants. Developed for high-performance refrigerators using ammonia as a refrigerant.

HFC Refrigerants

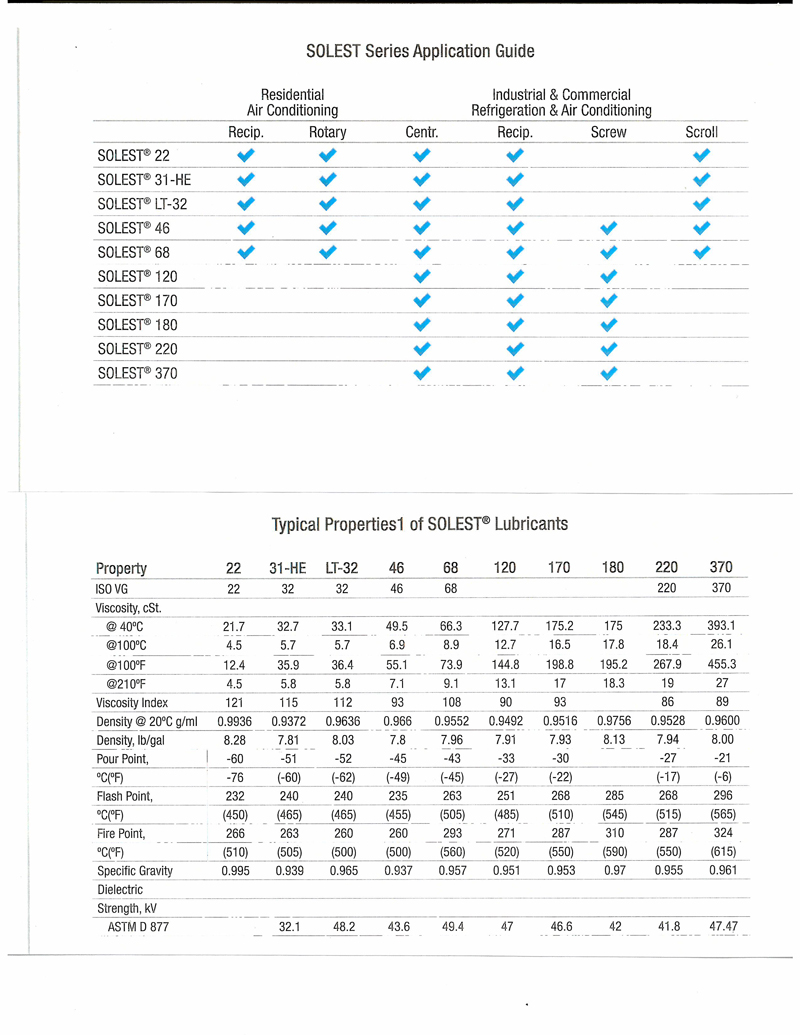

The Solest Series products are formulated from modified ester base stocks to provide controlled miscibility, as well as solubility with all HFC based refrigerants, including R-134a. They are mineral oil compatible and can be used to effectively retrofit an existing CFC based system. The controlled miscibility and solubility properties of the lubricants have led to improved volumetric efficiency in compressor tests, as well as providing efficient oil return from the system. In addition, tests conducted on the fluid have shown no loss of lubricant film under diluted conditions with rolling ball elements.

CFC & HCFC Refrigerants

This series of fluids are our alkyl benzene based products. These are typically used in applications such as R-502 and low temperature R-22 where additional miscibility is required.

CAMCO AB 150 | CAMCO AB 300 | CAMCO AB 500

CAMCO AB 150, CAMCO AB 300 and CAMCO AB 500 are new alkylbenzene type synthetic refrigeration compressor lubricating oils. Their viscosity levels are 150, 300 and 500 SSU 100ºF respectively. They are of highest quality, 100% synthetic oils having properties especially selected to insure long trouble-free life in all types of refrigeration, air conditioning and heat pump compressor service applications.

Features

SUPERIOR LOW TEMPERATURE PERFORMANCE — As measured by the ASHRAE Standard “Floc Point” test which shows the temperature at which a wax precipitate “flocs”, or drops out of an oil-refrigerant mixture under specified conditions. Alkylbenzene oils have no waxy components and therefore yield floc point values much lower than equal viscosity, conventional petroleum oils.

SOLUBILITY WITH REFRIGERANTS — CAMCO AB alkylbenzenes are significantly more soluble or “miscible” with all refrigerants than are conventional petroleum oils. This is a direct result of their chemical nature and is beneficial in reducing oil-refrigerant stratification or separation, in the operating system. The practical result of the good solubility properties of CAMCO AB 150, CAMCO AB 300 and CAMCO AB 500 is lower fluid viscosity in the evaporator and in suction return lines. This assures that oil will be returned to the compressor crankcase to maintain an oil film and extend compressor life.

EXCELLENT COMPATIBILITY — CAMCO AB alkylbenzene oils are fully compatible with all of the variety of materials including metals, wire coatings, varnishes, etc. that are present in a refrigeration system. They do not react with those materials to form sludges or deposits, even under severe operating conditions.

Physical Properties

CAMCO AB's are light in color, clear in appearance and are easy and safe to handle and use. They are non-toxic. They also have improved foaming properties, with less tendency to foam in mixtures with refrigerants under the varying conditions of compressor system service. CAMCO AB's are fully compatible with all refrigeration oils of conventional petroleum and alkylbenzene types.

This series are made from naphthenic base crudes that are highly refined to provide proper lubrication in refrigeration and air-conditioning compressors with various types of refrigerants.

CAMCO RO-Series are made from napthenic base crudes that are highly refined to provide proper lubrication in refrigeration and air conditioning compressors with various types of refrigerants.

For use in compressors: Rotary, Centrifugal, Reciprocating.

Using refrigerants: 11, 12, 22, 113, 114, 502

Methyl Chloride, Carbon Dioxide.

OEM Approved and used by major manufacturers.

Excellent thermal and chemical stability. Resistance to high temperature with the ability to remain chemically stable in the presence of other components.

Low POUR point to prevent separated oil from congealing.

Low FLOC point. Oil is wax free to provide excellent low temperature characteristics.

CAMCO Oils are compatible with Texaco, Suniso and Zerol and can be used as a replacement for them.

These fluids exhibit excellent thermal and chemical stability, natural lubricity with HCFC refrigerants, and good low temperature solubility.

CAMCO 4214-68 | CAMCO 4214-100 | CAMCO 4214-150 | CAMCO 4214-320

The CAMCO 4214 Series fluids are new technology refrigeration compressor lubricants.

Product Description

These proprietary fluids offer the advantages of excellent natural lubricity, excellent thermal and chemical stability with CFC refrigerants, a wide range of viscosity grades and solubility with certain refrigerants such as R-22 to very low temperatures. The availability of higher viscosity grades make these fluids an excellent choice for applications such as rotary screw compressors. A higher working viscosity allows for a better seal between rotors and provides better lubrications to bearings and seals. Good solubility at low temperatures assures lubricant return from flooded evaporators and better exchanger efficiency. Extremely low volatility provides improved lubricant/gas separation with coalescing filters.

Studies are currently in progress to examine potential energy savings in rotary screw compressors.

Consult CAMCO Lubricants for information on suitability for particular refrigeration applications.

This is a Naphthenic-based lubricant for fluorocarbon refrigerants.

The CAMCO® Pale Oil Refrigeration Fluids are designed for use as cost effective fluids in general refrigeration applications.

The fluids are refined from carefully chosen wax free napthenic crude oil basestocks to ensure the optimum quality product.

CAMCO® PALE OIL TYPICAL PROPERTIES

| 32 ISO | 46 ISO | 68 ISO | 100 ISO | |

|---|---|---|---|---|

| Viscosity (eSt) ASTM D445 | ||||

| @ 40°C | 30.7 | 42.4 | 60.7 | 92.44 |

| @ 100°C | 4.6 | 5.7 | 7.0 | 8.72 |

| @ 100°F | 34.1 | 47.4 | 68.5 | 105.53 |

| @ 210°F | 4.7 | 5.8 | 7.2 | 8.98 |

| Viscosity Index | 117 | 59 | 65 | 50 |

| Density (lbs./gal) | 7.42 | 7.49 | 7.52 | 7.58 |

| API Gravity ASTM D287 | 27.5 | 26.2 | 24.8 | 24 |

| Moisture (ppm) ASTM D174 | <50 | <50 | <50 | <50 |

| Total Acid Number (mg KOH/g) ASTM D974 | 0.05 | 0.05 | 0.05 | 0.05 |

| Flash Point (°F) ASTM D92 | 330 | 335 | 345 | 400 |

| Fire Point (°F) | 345 | 350 | 360 | 420 |

| Pour Point (°F) ASTM D97 | -50 | -45 | -40 | -12 |

| Floc Point (°F) | -50 | -45 | -35 | -30 |

| Aniline Point(°F) ASTM D611 | 185 | 195 | 200 | 205 |

| Dielectric Strength (kV) ASTM D877 | 29.1 | 35.5 | 41.9 | 41.8 |

| Sealed Glass Tube Test ANSI/ASHRAE 97 | ||||

| R-12 Purity | 98.9 | 98.9 | 98.9 | 98.9 |

| R-22 Formation | 1.1 | 1.1 | 1.1 | 1.1 |

| Copper Strip Test | 1a | 1a | 1a | 1a |

| Color ASTM D15001 | 1 | 1 | 1 | 1 |

These fluids are designed for use in all CFC and HCFC applications. They offer additional miscibility over conventional mineral oils, but do not have the excessive thinning that can be seen with alkyl benzene based products.

The Lenoil Refrigeration Fluids are a unique blend of synthetic and semi-synthetic basestocks designed to give optimum performance in a variety of refrigeration systems.

In addition to their outstanding stability with R-12 and R-22, the Lenoil fluids also contain a high degree of compatibility with these refrigerants, making them suitable for use even at low temperatures where convention mineral oil based products often fail.

Propane & Hydrocarbon Refrigeration

These are polyglycol-based lubricants which will resist dilution with hydrocarbon gases such as propane and butane, improving efficiency and lubricating viscosity.

CAMCO® PAG 16 Series are a unique custom blend of polyalkylene glycols with additives for oxidation stability, corrosion protection, metal de-activators and lubricity. The ability of these lubricants to withstand dilution by hydrocarbon and other compressed gases are particularly advantageous in flooded screw compressors. Other advantages include stability, low ash content, high viscosity index, shear stability and excellent lubricity.

CAMCO® PAG 16 Series is an excellent lubricant for worm gears. It will not stain yellow metals and offers as much as 18% energy savings over conventional mineral oil based gear oils.

TYPICAL PROPERTIES *

| PAG 16-32 | PAG 16-46 | PAG 16-68 | |

|---|---|---|---|

| Viscosity, ASTM D445 cSt | |||

| @ 210°F | 7.16 | 8.33 | 11.0 |

| @ 100°F | 32.2 | 50.03 | 67.2 |

| @ 40°C | 29.9 | 45.71 | 61.5 |

| @ 100°C | 7.02 | 8.149 | 10.8 |

| Viscosity Index, ASTM D2270 | 210 | 153 | 168 |

| Density, Ibs./gal | 8.22 | 8.21 | 8.25 |

| Pour Point, °F(°C) | -55 (-48) | -55 (-48) | -55 (-48) |

| Flash Point, °F(°C) | 400 (2049) | 500 (260) | 425 (218) |

| Fire Point, °F(°C) | 445 (229) | 540 (282) | 465 (241) |

| Specific Gravity, 20/20°C | 0.98 | 0.985 | 0.989 |

CO2 Refrigeration Oils

CAMCO® FMO 4624-68 and FMO 4624-100 are specifically designed for CO2 refrigeration compressors. The FMO 4624 Series are custom-blended synthetic hydrocarbon fluids giving improved lubrication at high and low temperatures, reduced volatility, and compatibility with mineral oils. Contains inhibitors to protect against corrosion and oxidation.

CAMCO® FMO 4624-68 and FMO 4624-100 are long-life food grade lubricants specially processed for use as sealing fluids for chemical processing pumps, compressor lubricant & coolant, and other applications requiring improved chemical stability.

These oils comply with FDA 21CFR 178.3570 – Lubricants with Incidental Food Contact.

TYPICAL PROPERTIES

| CAMCO® FMO 4624-68 | CAMCO® FMO 4624-100 | |

|---|---|---|

| Viscosity @ 40°C cSt ASTM D445 | 68.5 | 100.3 |

| Viscosity @ 100°C cs | 10.4 | 13.7 |

| Viscosity @ 100°F | 75.7 | 111.4 |

| Viscosity @ 210°F | 10.7 | 14.1 |

| Viscosity Index, ASTM D2270 | 140 | 138 |

| Density, lb./gal, 60°F | 6.96 | 6.99 |

| Pour Point °F (°C) ASTM D97 | -60 (-51) | -55 (-52) |

| Flash Point, C.O.C., °F (°C) ASTM D92 | (271) 519 | (268) 521 |

| Fire Point, C.O.C., °F (°C) ASTM D92 | (301) 568 | (298) 574 |

| Specific Gravity, ASTM D1298 | 0.835 | 0.839 |

**These values are not intended for use in preparing specifications.**

A custom formulated Polyolester (POE) synthetic lubricant series suitable for certain refrigeration applications such as with Carbon Dioxide and hydrocarbon refrigerants. Benefits include: excellent lubricity, improved low temperature characteristic and higher efficiency. Very low volatility can improve oil separation in equipment designed with coalescing elements and improve seal lubrication.

Typical Applications:

Reciprocating, Rotary Vane,Scroll, Centrifugal & Screw

CAMCO® RPC Series is formulated with triaryl phosphates as antiwear additives.

The special type of polyolesters used in these products has been found to offer less dilution and higher viscosity for better lubricity at higher compressor operating pressures and temperatures. The result is improved lubrication and compression sealing efficiency and better oil return when compared to other types of POE based products.

TYPICAL PROPERTIES *

| PROPERTY | METHOD | UNIT | RPC-46 | RPC-55 | RPC-68 | RPC-85 | RPC-130 | RPC-170 |

|---|---|---|---|---|---|---|---|---|

| Viscosity | ASTM D445 | cSt @ 40°C | 46 | 55 | 66 | 80 | 136 | 178 |

| Viscosity | ASTM D445 | cSt @ 100°C | 8.1 | 9.1 | 10.6 | 12.2 | 17 | 18.5 |

| Viscosity Index | ASTM D2270 | 150 | 145 | 151 | 148 | 143 | 116 | |

| Density 20°C (68°F) | g/cc Pounds/galIon | 0.972 8.11 | 0.976 8.14 | 0.983 8.19 | 0.985 8.215 | 0.98 8.17 | 0.975 8.13 | |

| Flash Point | ASTM D-92 | °C (°F) | >250 (482) | >260 (500) | >260 (500) | >280 (536) | >280 (536) | >280 (536) |

| Pour Point* | ASTM D-97 | °C (°F) | -49 (-56) | -48 (-54) | -48 (-54) | -40 (-40) | -36 (-33) | -36 (-33) |

| Total Acid Number | AST D-664 | mg KOH/g | <0.06 | <0.06 | <0.1 | <0.1 | <0.1 | <0.1 |

| Evaporation loss 6.5 hours at 204°C (400°F) | ASTM D-972 | percent | 3 | 3 | 3 | 3 | 3 | 3 |

| Water Content | ASTM D‑1744 | ppm | <50 | <50 | <50 | <50 | <50 | <50 |

* These values are not intended for use in preparing specifications.

Call (763) 205-0828 to place your order today.